List of Tables

Table 1. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Value by Type, (US$ Million) & (2024 VS 2031)

Table 2. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Value by Application, (US$ Million) & (2024 VS 2031)

Table 3. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Capacity (Tons) by Manufacturers in 2024

Table 4. Global Thermal Conductive Potting Compound for New Energy Vehicles Production by Manufacturers (2020-2025) & (Tons)

Table 5. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share by Manufacturers (2020-2025)

Table 6. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value by Manufacturers (2020-2025) & (US$ Million)

Table 7. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Share by Manufacturers (2020-2025)

Table 8. Global Key Players of Thermal Conductive Potting Compound for New Energy Vehicles, Industry Ranking, 2023 VS 2024

Table 9. Company Type (Tier 1, Tier 2, and Tier 3) & (based on the Production Value in Thermal Conductive Potting Compound for New Energy Vehicles as of 2024)

Table 10. Global Market Thermal Conductive Potting Compound for New Energy Vehicles Average Price by Manufacturers (US$/kg) & (2020-2025)

Table 11. Global Key Manufacturers of Thermal Conductive Potting Compound for New Energy Vehicles, Manufacturing Base Distribution and Headquarters

Table 12. Global Key Manufacturers of Thermal Conductive Potting Compound for New Energy Vehicles, Product Offered and Application

Table 13. Global Key Manufacturers of Thermal Conductive Potting Compound for New Energy Vehicles, Date of Enter into This Industry

Table 14. Global Thermal Conductive Potting Compound for New Energy Vehicles Manufacturers Market Concentration Ratio (CR5 and HHI)

Table 15. Mergers & Acquisitions, Expansion Plans

Table 16. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value by Region: 2020 VS 2024 VS 2031 (US$ Million)

Table 17. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) by Region (2020-2025)

Table 18. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Market Share by Region (2020-2025)

Table 19. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) Forecast by Region (2026-2031)

Table 20. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Market Share Forecast by Region (2026-2031)

Table 21. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Comparison by Region: 2020 VS 2024 VS 2031 (Tons)

Table 22. Global Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons) by Region (2020-2025)

Table 23. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share by Region (2020-2025)

Table 24. Global Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons) Forecast by Region (2026-2031)

Table 25. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share Forecast by Region (2026-2031)

Table 26. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Average Price (US$/kg) by Region (2020-2025)

Table 27. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Average Price (US$/kg) by Region (2026-2031)

Table 28. Global Thermal Conductive Potting Compound for New Energy Vehicles Consumption Growth Rate by Region: 2020 VS 2024 VS 2031 (Tons)

Table 29. Global Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Region (2020-2025) & (Tons)

Table 30. Global Thermal Conductive Potting Compound for New Energy Vehicles Consumption Market Share by Region (2020-2025)

Table 31. Global Thermal Conductive Potting Compound for New Energy Vehicles Forecasted Consumption by Region (2026-2031) & (Tons)

Table 32. Global Thermal Conductive Potting Compound for New Energy Vehicles Forecasted Consumption Market Share by Region (2026-2031)

Table 33. North America Thermal Conductive Potting Compound for New Energy Vehicles Consumption Growth Rate by Country: 2020 VS 2024 VS 2031 (Tons)

Table 34. North America Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Country (2020-2025) & (Tons)

Table 35. North America Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Country (2026-2031) & (Tons)

Table 36. Europe Thermal Conductive Potting Compound for New Energy Vehicles Consumption Growth Rate by Country: 2020 VS 2024 VS 2031 (Tons)

Table 37. Europe Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Country (2020-2025) & (Tons)

Table 38. Europe Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Country (2026-2031) & (Tons)

Table 39. Asia Pacific Thermal Conductive Potting Compound for New Energy Vehicles Consumption Growth Rate by Region: 2020 VS 2024 VS 2031 (Tons)

Table 40. Asia Pacific Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Region (2020-2025) & (Tons)

Table 41. Asia Pacific Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Region (2026-2031) & (Tons)

Table 42. Latin America, Middle East & Africa Thermal Conductive Potting Compound for New Energy Vehicles Consumption Growth Rate by Country: 2020 VS 2024 VS 2031 (Tons)

Table 43. Latin America, Middle East & Africa Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Country (2020-2025) & (Tons)

Table 44. Latin America, Middle East & Africa Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Country (2026-2031) & (Tons)

Table 45. Global Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons) by Type (2020-2025)

Table 46. Global Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons) by Type (2026-2031)

Table 47. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share by Type (2020-2025)

Table 48. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share by Type (2026-2031)

Table 49. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) by Type (2020-2025)

Table 50. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) by Type (2026-2031)

Table 51. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Market Share by Type (2020-2025)

Table 52. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Market Share by Type (2026-2031)

Table 53. Global Thermal Conductive Potting Compound for New Energy Vehicles Price (US$/kg) by Type (2020-2025)

Table 54. Global Thermal Conductive Potting Compound for New Energy Vehicles Price (US$/kg) by Type (2026-2031)

Table 55. Global Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons) by Application (2020-2025)

Table 56. Global Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons) by Application (2026-2031)

Table 57. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share by Application (2020-2025)

Table 58. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share by Application (2026-2031)

Table 59. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) by Application (2020-2025)

Table 60. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) by Application (2026-2031)

Table 61. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Market Share by Application (2020-2025)

Table 62. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Market Share by Application (2026-2031)

Table 63. Global Thermal Conductive Potting Compound for New Energy Vehicles Price (US$/kg) by Application (2020-2025)

Table 64. Global Thermal Conductive Potting Compound for New Energy Vehicles Price (US$/kg) by Application (2026-2031)

Table 65. Henkel Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 66. Henkel Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 67. Henkel Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 68. Henkel Main Business and Markets Served

Table 69. Henkel Recent Developments/Updates

Table 70. Parker Hannifin Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 71. Parker Hannifin Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 72. Parker Hannifin Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 73. Parker Hannifin Main Business and Markets Served

Table 74. Parker Hannifin Recent Developments/Updates

Table 75. Dow Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 76. Dow Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 77. Dow Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 78. Dow Main Business and Markets Served

Table 79. Dow Recent Developments/Updates

Table 80. Shin-Etsu Chemical Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 81. Shin-Etsu Chemical Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 82. Shin-Etsu Chemical Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 83. Shin-Etsu Chemical Main Business and Markets Served

Table 84. Shin-Etsu Chemical Recent Developments/Updates

Table 85. Wacker Chemie Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 86. Wacker Chemie Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 87. Wacker Chemie Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 88. Wacker Chemie Main Business and Markets Served

Table 89. Wacker Chemie Recent Developments/Updates

Table 90. ITW Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 91. ITW Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 92. ITW Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 93. ITW Main Business and Markets Served

Table 94. ITW Recent Developments/Updates

Table 95. H.B. Fuller Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 96. H.B. Fuller Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 97. H.B. Fuller Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 98. H.B. Fuller Main Business and Markets Served

Table 99. H.B. Fuller Recent Developments/Updates

Table 100. 3M Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 101. 3M Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 102. 3M Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 103. 3M Main Business and Markets Served

Table 104. 3M Recent Developments/Updates

Table 105. Momentive Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 106. Momentive Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 107. Momentive Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 108. Momentive Main Business and Markets Served

Table 109. Momentive Recent Developments/Updates

Table 110. Huitian New Materials Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 111. Huitian New Materials Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 112. Huitian New Materials Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 113. Huitian New Materials Main Business and Markets Served

Table 114. Huitian New Materials Recent Developments/Updates

Table 115. BeGinor Material Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 116. BeGinor Material Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 117. BeGinor Material Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 118. BeGinor Material Main Business and Markets Served

Table 119. BeGinor Material Recent Developments/Updates

Table 120. Shenzhen Duopang Technology Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 121. Shenzhen Duopang Technology Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 122. Shenzhen Duopang Technology Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 123. Shenzhen Duopang Technology Main Business and Markets Served

Table 124. Shenzhen Duopang Technology Recent Developments/Updates

Table 125. Yuwo Rui New Material Thermal Conductive Potting Compound for New Energy Vehicles Company Information

Table 126. Yuwo Rui New Material Thermal Conductive Potting Compound for New Energy Vehicles Specification and Application

Table 127. Yuwo Rui New Material Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons), Value (US$ Million), Price (US$/kg) and Gross Margin (2020-2025)

Table 128. Yuwo Rui New Material Main Business and Markets Served

Table 129. Yuwo Rui New Material Recent Developments/Updates

Table 130. Key Raw Materials Lists

Table 131. Raw Materials Key Suppliers Lists

Table 132. Thermal Conductive Potting Compound for New Energy Vehicles Distributors List

Table 133. Thermal Conductive Potting Compound for New Energy Vehicles Customers List

Table 134. Thermal Conductive Potting Compound for New Energy Vehicles Market Trends

Table 135. Thermal Conductive Potting Compound for New Energy Vehicles Market Drivers

Table 136. Thermal Conductive Potting Compound for New Energy Vehicles Market Challenges

Table 137. Thermal Conductive Potting Compound for New Energy Vehicles Market Restraints

Table 138. Research Programs/Design for This Report

Table 139. Key Data Information from Secondary Sources

Table 140. Key Data Information from Primary Sources

Table 141. Authors List of This Report

List of Figures

Figure 1. Product Picture of Thermal Conductive Potting Compound for New Energy Vehicles

Figure 2. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Value by Type, (US$ Million) & (2020-2031)

Figure 3. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Share by Type: 2024 VS 2031

Figure 4. Silicone-Based Product Picture

Figure 5. Non-Silicone-Based Product Picture

Figure 6. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Value by Application, (US$ Million) & (2020-2031)

Figure 7. Global Thermal Conductive Potting Compound for New Energy Vehicles Market Share by Application: 2024 VS 2031

Figure 8. Application One

Figure 9. Application Two

Figure 10. Application Three

Figure 11. Application Four

Figure 12. Application Five

Figure 13. Application Six

Figure 14. Application Seven

Figure 15. Application Eight

Figure 16. Application Nine

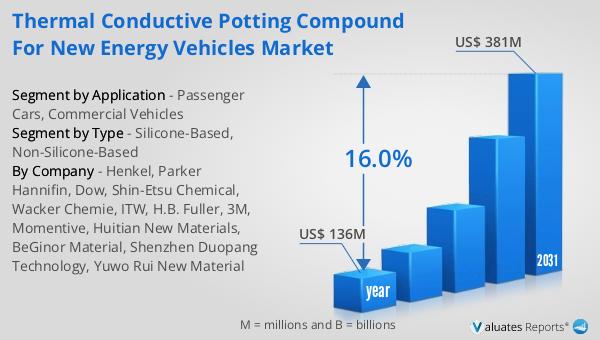

Figure 17. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million), 2020 VS 2024 VS 2031

Figure 18. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) & (2020-2031)

Figure 19. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Capacity (Tons) & (2020-2031)

Figure 20. Global Thermal Conductive Potting Compound for New Energy Vehicles Production (Tons) & (2020-2031)

Figure 21. Global Thermal Conductive Potting Compound for New Energy Vehicles Average Price (US$/kg) & (2020-2031)

Figure 22. Thermal Conductive Potting Compound for New Energy Vehicles Report Years Considered

Figure 23. Thermal Conductive Potting Compound for New Energy Vehicles Production Share by Manufacturers in 2024

Figure 24. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Share by Manufacturers (2024)

Figure 25. Thermal Conductive Potting Compound for New Energy Vehicles Market Share by Company Type (Tier 1, Tier 2, and Tier 3): 2020 VS 2024

Figure 26. The Global 5 and 10 Largest Players: Market Share by Thermal Conductive Potting Compound for New Energy Vehicles Revenue in 2024

Figure 27. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value by Region: 2020 VS 2024 VS 2031 (US$ Million)

Figure 28. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Value Market Share by Region: 2020 VS 2024 VS 2031

Figure 29. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Comparison by Region: 2020 VS 2024 VS 2031 (Tons)

Figure 30. Global Thermal Conductive Potting Compound for New Energy Vehicles Production Market Share by Region: 2020 VS 2024 VS 2031

Figure 31. North America Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) Growth Rate (2020-2031)

Figure 32. Europe Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) Growth Rate (2020-2031)

Figure 33. China Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) Growth Rate (2020-2031)

Figure 34. Japan Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) Growth Rate (2020-2031)

Figure 35. India Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) Growth Rate (2020-2031)

Figure 36. Southeast Asia Thermal Conductive Potting Compound for New Energy Vehicles Production Value (US$ Million) Growth Rate (2020-2031)

Figure 37. Global Thermal Conductive Potting Compound for New Energy Vehicles Consumption by Region: 2020 VS 2024 VS 2031 (Tons)

Figure 38. Global Thermal Conductive Potting Compound for New Energy Vehicles Consumption Market Share by Region: 2020 VS 2024 VS 2031

Figure 39. North America Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 40. North America Thermal Conductive Potting Compound for New Energy Vehicles Consumption Market Share by Country (2020-2031)

Figure 41. U.S. Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 42. Canada Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 43. Europe Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 44. Europe Thermal Conductive Potting Compound for New Energy Vehicles Consumption Market Share by Country (2020-2031)

Figure 45. Germany Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 46. France Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 47. U.K. Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 48. Italy Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 49. Russia Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 50. Asia Pacific Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 51. Asia Pacific Thermal Conductive Potting Compound for New Energy Vehicles Consumption Market Share by Region (2020-2031)

Figure 52. China Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 53. Japan Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 54. South Korea Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 55. China Taiwan Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 56. Southeast Asia Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 57. India Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 58. Latin America, Middle East & Africa Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 59. Latin America, Middle East & Africa Thermal Conductive Potting Compound for New Energy Vehicles Consumption Market Share by Country (2020-2031)

Figure 60. Mexico Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 61. Brazil Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 62. Turkey Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 63. GCC Countries Thermal Conductive Potting Compound for New Energy Vehicles Consumption and Growth Rate (2020-2031) & (Tons)

Figure 64. Global Production Market Share of Thermal Conductive Potting Compound for New Energy Vehicles by Type (2020-2031)

Figure 65. Global Production Value Market Share of Thermal Conductive Potting Compound for New Energy Vehicles by Type (2020-2031)

Figure 66. Global Thermal Conductive Potting Compound for New Energy Vehicles Price (US$/kg) by Type (2020-2031)

Figure 67. Global Production Market Share of Thermal Conductive Potting Compound for New Energy Vehicles by Application (2020-2031)

Figure 68. Global Production Value Market Share of Thermal Conductive Potting Compound for New Energy Vehicles by Application (2020-2031)

Figure 69. Global Thermal Conductive Potting Compound for New Energy Vehicles Price (US$/kg) by Application (2020-2031)

Figure 70. Thermal Conductive Potting Compound for New Energy Vehicles Value Chain

Figure 71. Channels of Distribution (Direct Vs Distribution)

Figure 72. Bottom-up and Top-down Approaches for This Report

Figure 73. Data Triangulation